Can Your Electrical Equipment Survive a Sandstorm? Why IP67 Metal Enclosures Are the Answer

**The Advantages of IP67-Rated Metal Enclosures for Electrical Equipment in Sandy and Dusty Environments**

### **Introduction**

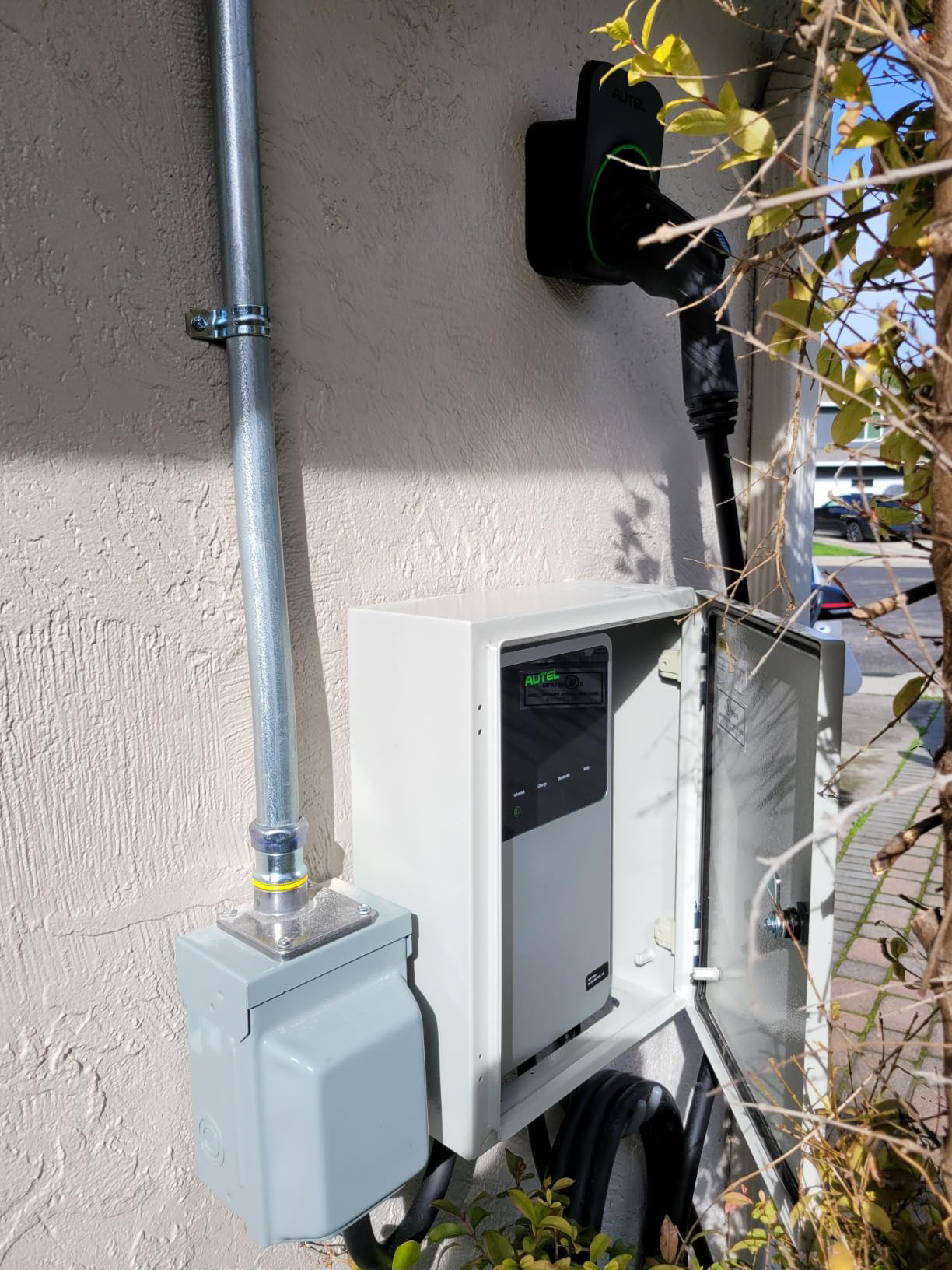

In harsh, wind-swept regions where sand and dust pose significant challenges to electrical infrastructure, **IP67-rated metal enclosures**

provide a robust solution. These enclosures ensure reliable performance, extended equipment lifespan, and reduced maintenance needs

—even in the most demanding conditions.

### **1. Understanding IP67 Protection**

The **IP67 (Ingress Protection) rating** signifies two key features:

- **Dust-tight (6):** Complete protection against fine particulate matter.

- **Waterproof (7):** Resistance to temporary immersion (up to 1 meter for 30 minutes).

This makes IP67 enclosures ideal for **deserts, construction sites, mining operations, and coastal areas** where abrasive sand, dust storms,

and moisture are constant threats.

### **2. Key Advantages in Sandy & Dusty Environments**

#### **A. Superior Dust and Sand Resistance**

- **Prevents Internal Contamination:** Fine sand particles can clog circuits, corrode contacts, and degrade insulation. IP67 metal enclosures

block all dust ingress, ensuring uninterrupted operation.

- **Reduces Abrasive Wear:** Unlike plastic housings, metal enclosures resist sandblasting effects, maintaining structural integrity over time.

#### **B. Enhanced Durability Against Extreme Weather**

- **Withstands High Winds & Flying Debris:** Reinforced metal construction prevents deformation from impact.

- **Corrosion-Resistant Coatings:** Powder-coated or stainless-steel options resist salt and sand-induced corrosion.

#### **C. Thermal Management in Hot, Sandy Climates**

- **Heat Dissipation:** Metal enclosures naturally conduct heat away from sensitive components, preventing overheating in high-temperature environments.

- **UV Resistance:** Unlike plastic, metal does not degrade under prolonged sun exposure.

#### **D. Water and Humidity Protection**

- **Resists Sudden Rain or Condensation:** Even in arid regions, occasional moisture (e.g., dew, flash floods) can damage electronics. IP67 sealing prevents internal water damage.

### **3. Applications in Wind-Swept Regions**

- **Solar Power Plants** (e.g., desert solar farms)

- **Oil & Gas Installations** (e.g., drilling rigs in sandy terrain)

- **Telecommunication Towers** (e.g., remote base stations)

- **Military & Defense Equipment** (e.g., desert operations)

### **4. Comparison: Metal vs. Plastic Enclosures**

| Feature | IP67 Metal Enclosure | IP67 Plastic Enclosure |

| Sand Abrasion Resistance | Excellent | Moderate |

| Structural Strength | High (impact-resistant) | Lower (may crack) |

| Heat Dissipation | Efficient | Poor (insulative) |

| Longevity in UV/Sun | High | Prone to degradation |

### **5. Future Trends: Smart & Modular Designs**

- **Integrated Air Filters:** For active ventilation without dust ingress.

- **IoT-Enabled Monitoring:** Sensors to track internal conditions (temperature, humidity).

### **Conclusion**

In wind-swept, sandy environments, **IP67-rated metal enclosures** offer unmatched protection for electrical equipment.

Their combination of **dustproof sealing, rugged durability, and thermal stability** makes them the preferred choice for industries operating in extreme conditions.

Investing in high-quality metal enclosures translates to **fewer failures, lower maintenance costs, and higher system reliability**—critical factors for success in challenging climates.